Home

"POS Cobra" Restoration Journal

Titanium Motorsports Racing Journal

Parts & Stuff

For Sale

PRI Show

The Lounge

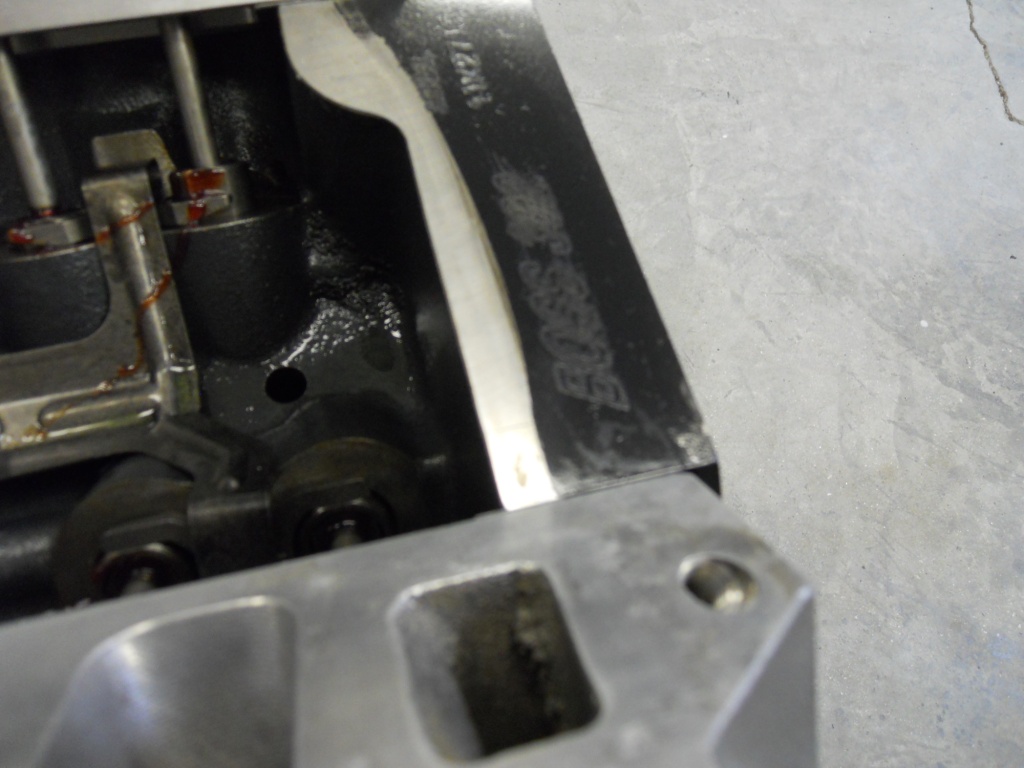

The rotating assembly of the motor was the same one from the prior motor, we just replaced the block with the Ford Racing "Boss 302" block. Buddy bored the motor .030 over, combined with the Eagle 3.25 stroke crank, gave the motor a displacement of 331 cubic inches.

After getting home, I proceeded to finish the motors assembly.

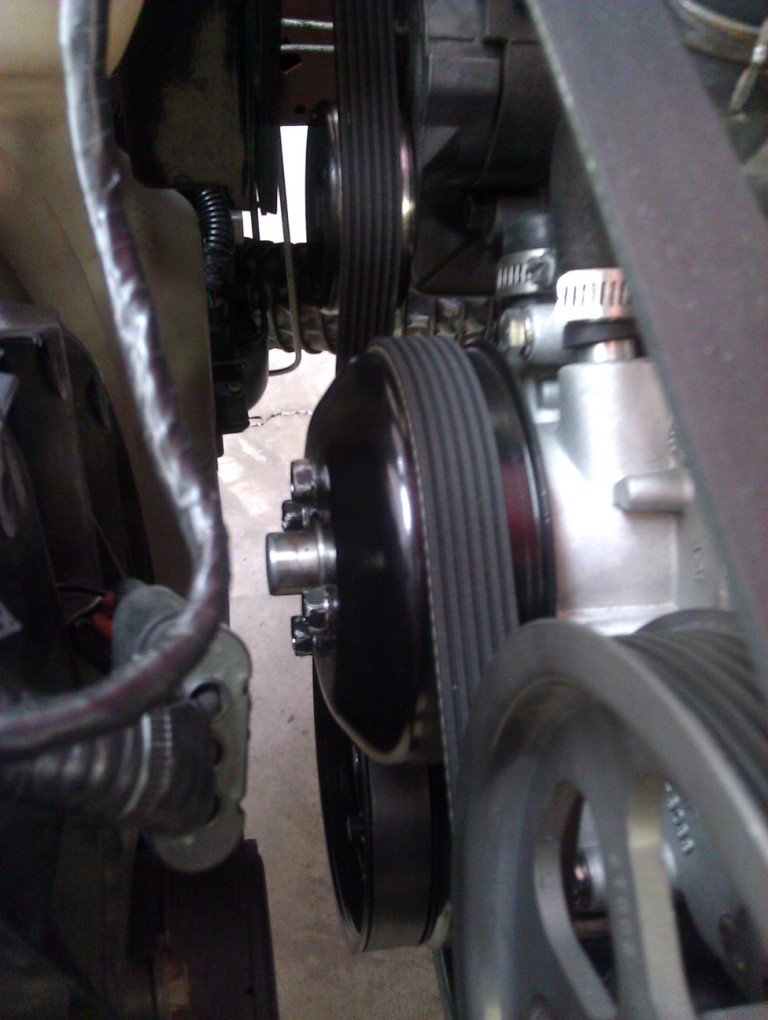

One issue I had that I did not expect was that my crank pulley would no longer fit correctly on the new ATI Super Dampner that Buddy installed. The small diameter of the underdrive crank pulley had the outer edge of the pulley up against the face of the balancer before the center flange of the pulley made contact with the balancer. I tried a stock pulley on the ATI dampner, which fit better, but still did not sit on the front of the balancer.

I called ATI, who said that this is a known issue with the 94-95 Mustang drive set-up, and that the pulley will need to be shimmed to fit correctly. The problem with shimming the crank pulley is that now all the other pulleys are out of alignment and will need to be shimmed out in order for the drive belt to line up.

In order for it all to fit correctly, the power steering pump, alternator and belt tensioner needed to come forward about 1/8 of an inch for the belt to line up correctly. The power steering pump was no problem. I use an aftermarket KRC racing pump, which has to be shimmed to your application anyway. So it was just a matter of adding two more shims to the pack.

I got lucky on the alternator too. I was able to shim the alternator forward within its mounting bracket, so no major modifications were required.

The belt tensioner and water pump pulley both ride on the 'back' of the belt (smooth-side), and as such, have a very wide contact area. This design means the water pump pulley required no shims, and the belt tensioner, just a small 1/16 of an inch.

The rest of the motor went back together and in the car with no further issues.